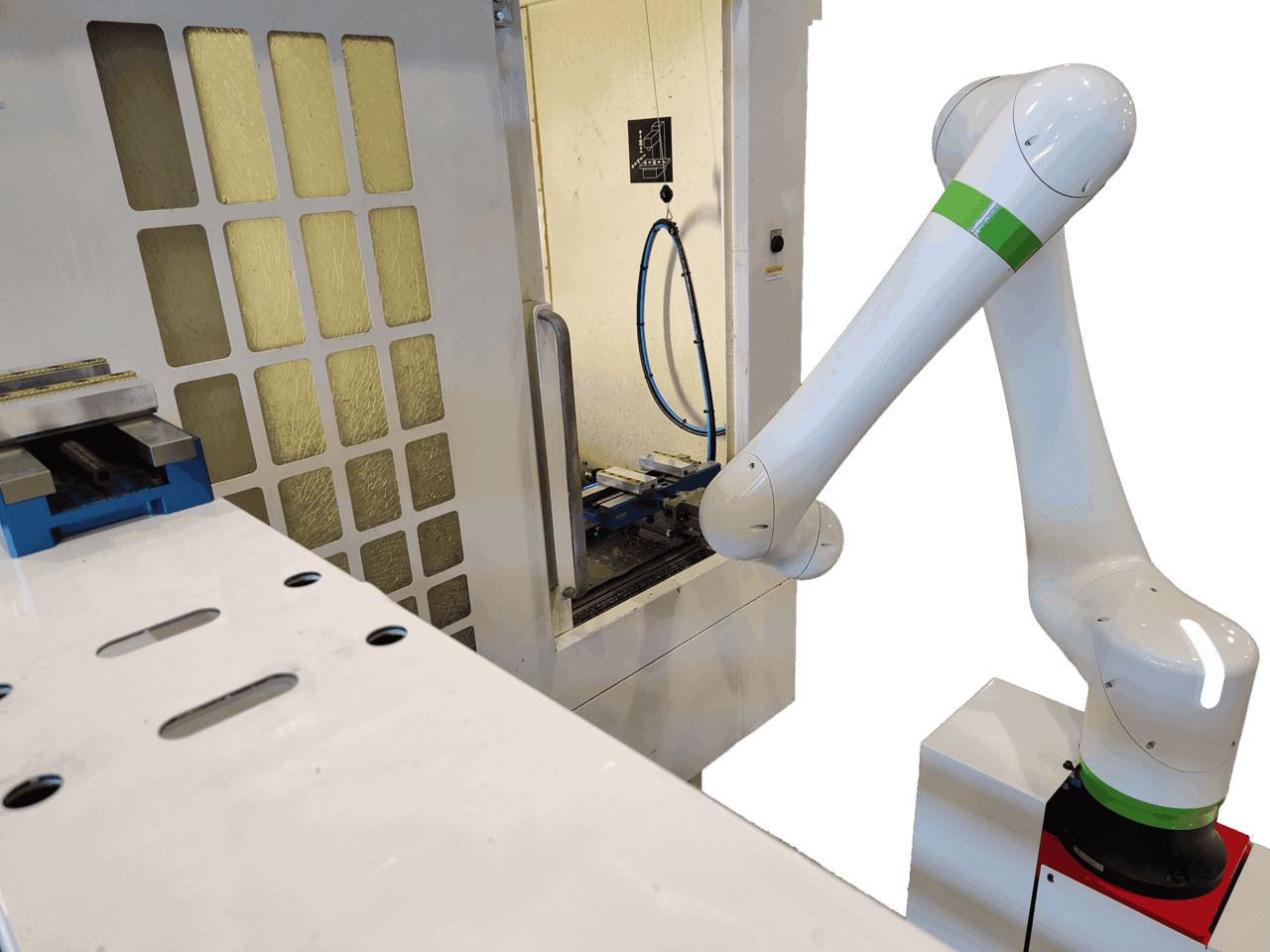

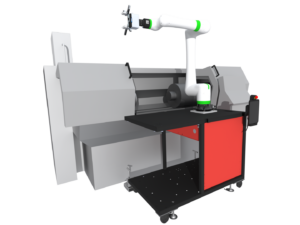

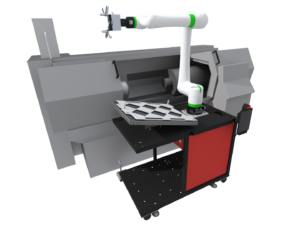

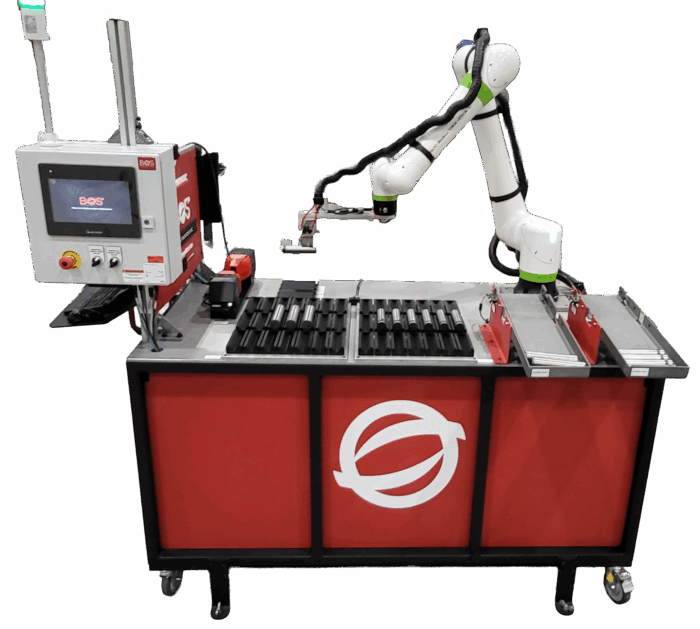

ROBOTIC MACHINE TENDING SOLUTIONS

Create capacity for growth through efficiency and safety

Address skilled labour shortages with robotic machine tending solutions from BOS. Robots can do the repetitive and physically demanding loading/unloading tasks so you can optimize utilization of your existing workforce. Ensure the competitiveness of your manufacturing by equipping it with leading-edge technology.

Automation can protect workers from hazardous conditions in the workplace by reducing injuries that happen due to fatigue or repetitive physical demands. It also significantly increases the efficiency of your manufacturing processes, translating to higher throughput.

Advanced Features

- Bin Picking & Advanced Inspection by TrueLight Machine Vision Solutions

- Remote Support & Performance Analytics by Proximity Smart Support™

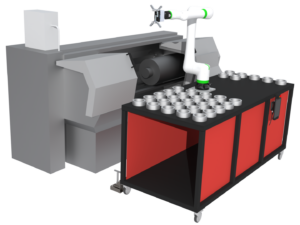

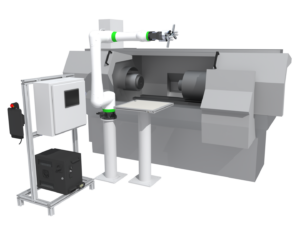

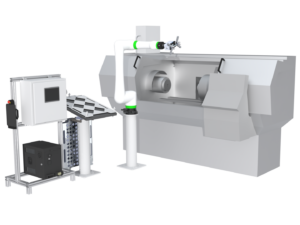

- Mobile & Docking Carts

- Palletizing-Ready

ROBOTIC MACHINE TENDING

Customization Available

With more than 25 years of automation integration expertise, we can customize any of the suggested configurations to meet your specific application requirements.

Vision Integration Capabilities

MAXIMIZE YOUR ROI WITH BOS ROBOTIC MACHINE TENDING SOLUTIONS

Ensure the competitiveness of your manufacturing by equipping it with leading-edge technology