SOLUCIONES ROBÓTICAS COLABORATIVAS PARA LA FABRICACIÓN

Imagina un mundo sin barreras de seguridad; un mundo en el que los humanos trabajen codo con codo con los robots de forma segura. En este mundo, los robots hacen todo el trabajo repetitivo extenuante, liberándonos para usar nuestro cerebro y destreza manual para hacer los trabajos más ligeros e intrincados.

Un robot colaborativo, o cobot, está construido para trabajar de forma segura junto a las personas para automatizar procesos en las fábricas o para otros fines. En el mundo industrial, los cobots son grandes ayudantes de los operarios cuyo valor está en el intrincado trabajo del producto.

Las tecnologías avanzadas han permitido a los ingenieros y programadores crear estos robots de manera que puedan reaccionar a la interacción humana, garantizando al mismo tiempo la seguridad de las personas. Esto es posible gracias a características de seguridad, como sensores, materiales ligeros, bordes redondeados y velocidad y fuerza limitadas.

Los robots colaborativos pueden utilizarse para levantar objetos, ejecutar tareas de manipulación repetitivas y peligrosas, ensamblar piezas de trabajo y colaborar con otros procesos de fabricación dentro de diversas industrias. Descubra cómo la automatización puede ayudar a su empresa.

Ventajas de los robots colaborativos

Los robots colaborativos pueden impulsar la productividad

Oportunidad de aumentar la rentabilidad

También pueden mejorar la ergonomía

Su negocio puede ser más exclusivo

Se pueden eliminar las tareas no cualificadas

Su empresa puede ser más competitiva

Soluciones Cobot de BOS

BOS tiene lo necesario para integrar soluciones personalizadas con robots colaborativos para sus necesidades específicas. De hecho, fuimos el primer integrador que instaló con éxito un cobot de FANUC en Ontario. A continuación se muestran un par de ejemplos en los que esta tecnología ha ayudado a los fabricantes.

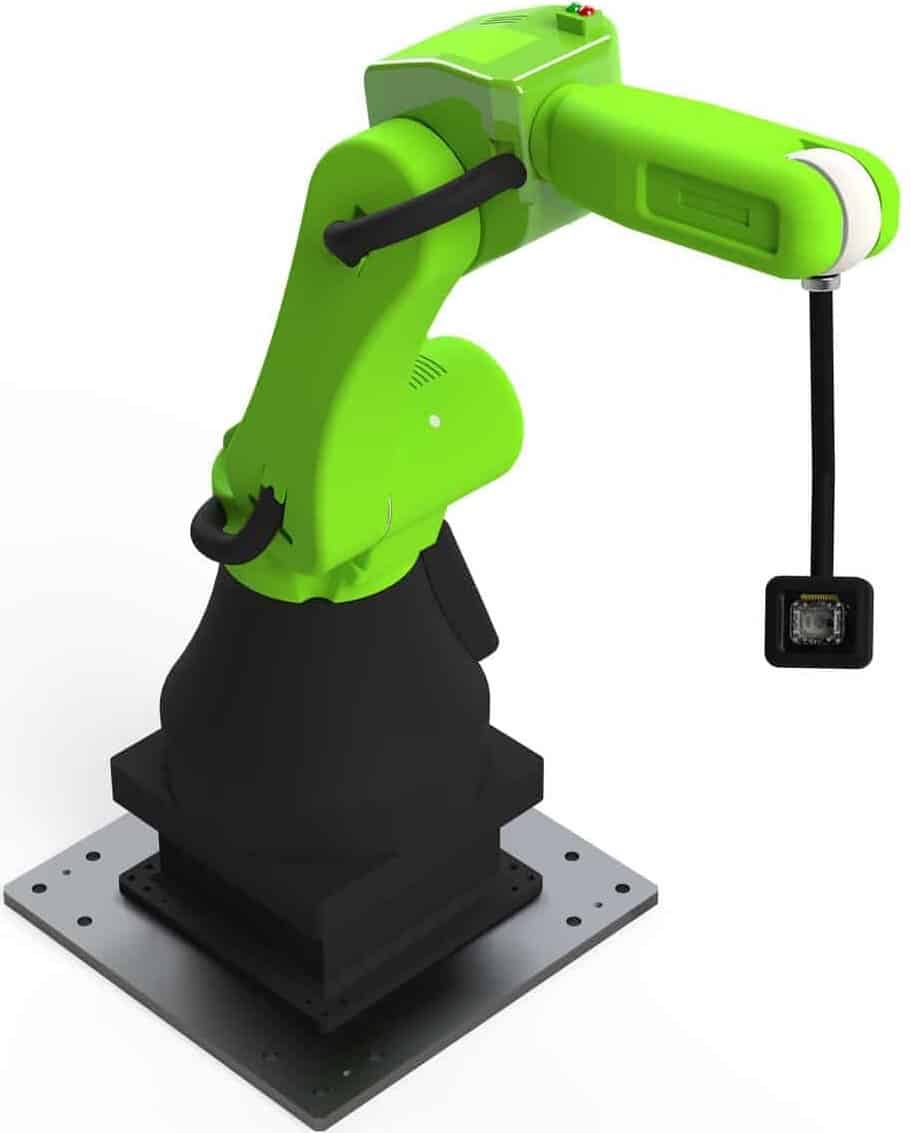

Robot asistente de control de calidad

Los robots colaborativos pueden ser un gran activo a la hora de seguir las operaciones del humano para comprobar y asegurar la calidad de las mismas. Arme su cobot con una cámara, sensores láser, equipos de prueba eléctrica y sondas para probar de forma eficiente y segura las piezas en el mismo lugar en el que se ensambló con un operario.

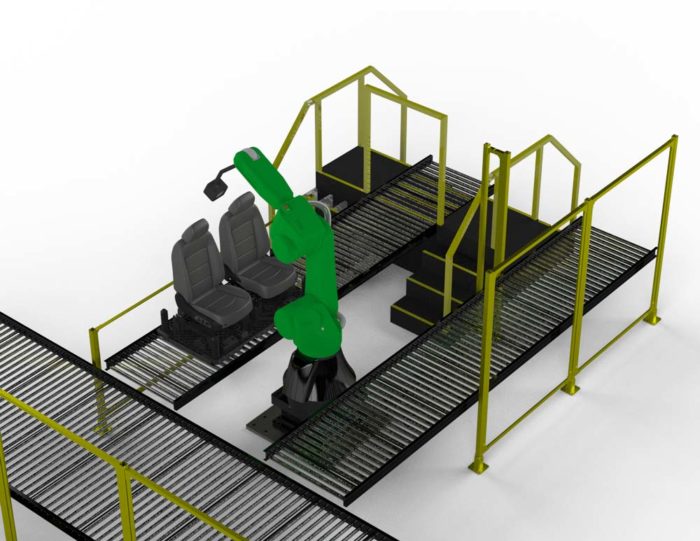

Robot asistente ergonomico para el operador

Prevenir el riesgo de lesiones por esfuerzo repetitivo entre los trabajadores de la línea de montaje y mejorar la productividad es una gran razón para considerar los robots colaborativos. Los cobots pueden elevar y posicionar los componentes por usted, o proporcionar una asistencia de elevación inteligente y adaptable cuando es guiada por el operario para una parte de la secuencia mientras se automatiza el resto de la secuencia.

Soluciones de fabricación avanzadas

¿No sabe por dónde empezar? Tenemos diseños modulares de eficacia probada para ayudarle a empezar. Si necesita algo un poco diferente, no hay problema, nuestros expertos están disponibles para personalizarlo solo para usted.

Consulte nuestra solución de inspección por visión de cobot (I-CV):

Robots colaborativos de FANUC

BOS Innovations es un integrador certificado de la serie CR de FANUC. Esta línea de productos, que ofrece cargas útiles de 4 kg, 7 kg, 10 kg, 14 kg, 15 kg y 35 kg y un alcance inigualable, es ideal para los procesos de manipulación que exponen a las personas al riesgo de sufrir lesiones por esfuerzos repetitivos y otras lesiones relacionadas con el trabajo. Precisos y repetibles, también le ofrecen enormes ventajas en términos de calidad y rendimiento. Más información sobre la línea de robots colaborativos de FANUC.

APRENDER MÁS SOBRE LA AUTOMATIZACIÓN

Contáctenos hoy y vea cómo podemos ayudarle a automatizar su negocio.