LASER CELLS

BOS® laser cells are turnkey solutions for automating industrial cutting or welding processes. Based on a modular, pre-engineered design, they can be customized to your needs to advance your manufacturing capabilities for the future. Increase competitiveness, productivity, quality, and profitability with BOS laser cells.

Features:

Pre-Engineered Design for Low Cost & Quick Delivery

Configurable & Modular

Ships Ready to Run

Drop-in-Place Installation

Operator Friendly

CSA & NFPA Safety Compliant Design

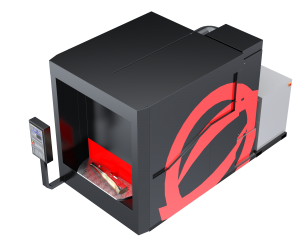

L-R

The BOS L-R solutions are configurable and based on a modular design, allowing you to meet changing market demands to ensure future competitiveness. The base model has a single robot with an integrated PLC control system and a flat table for part placement.

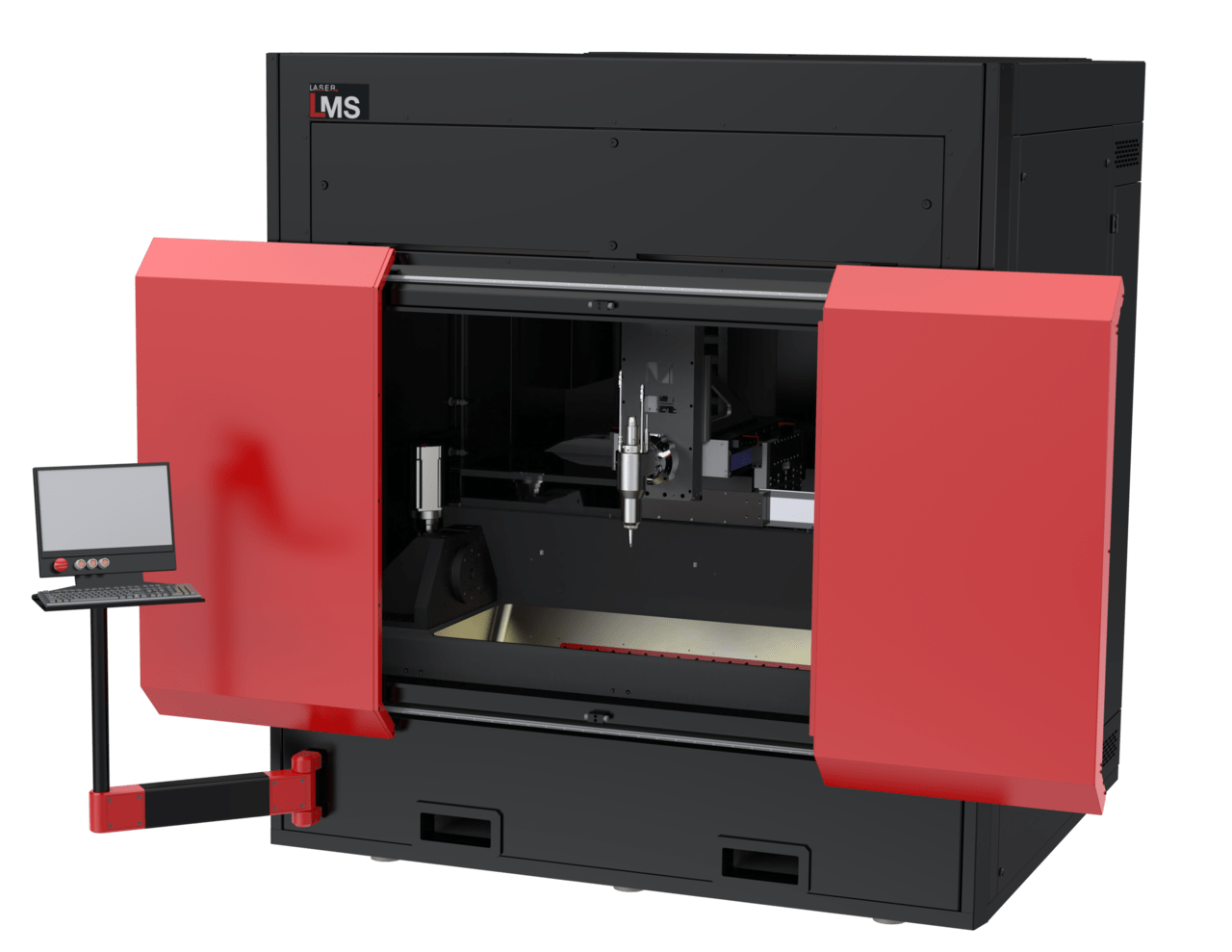

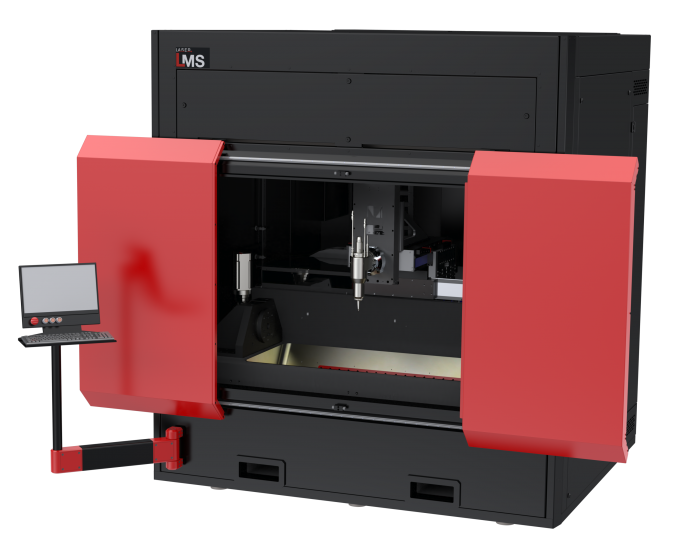

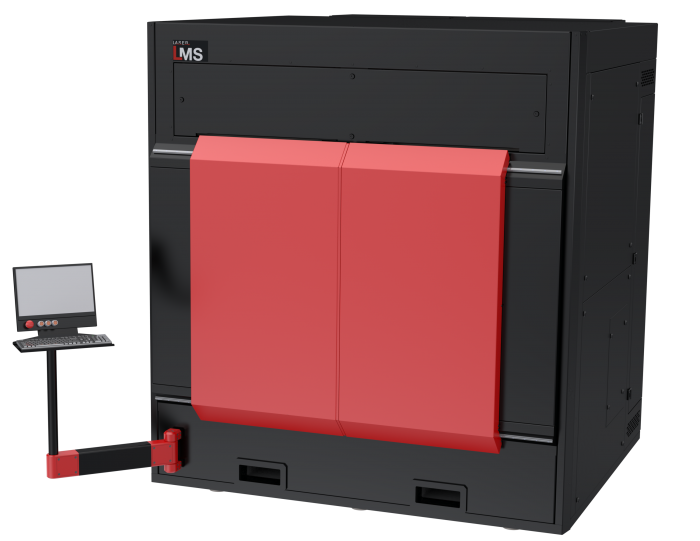

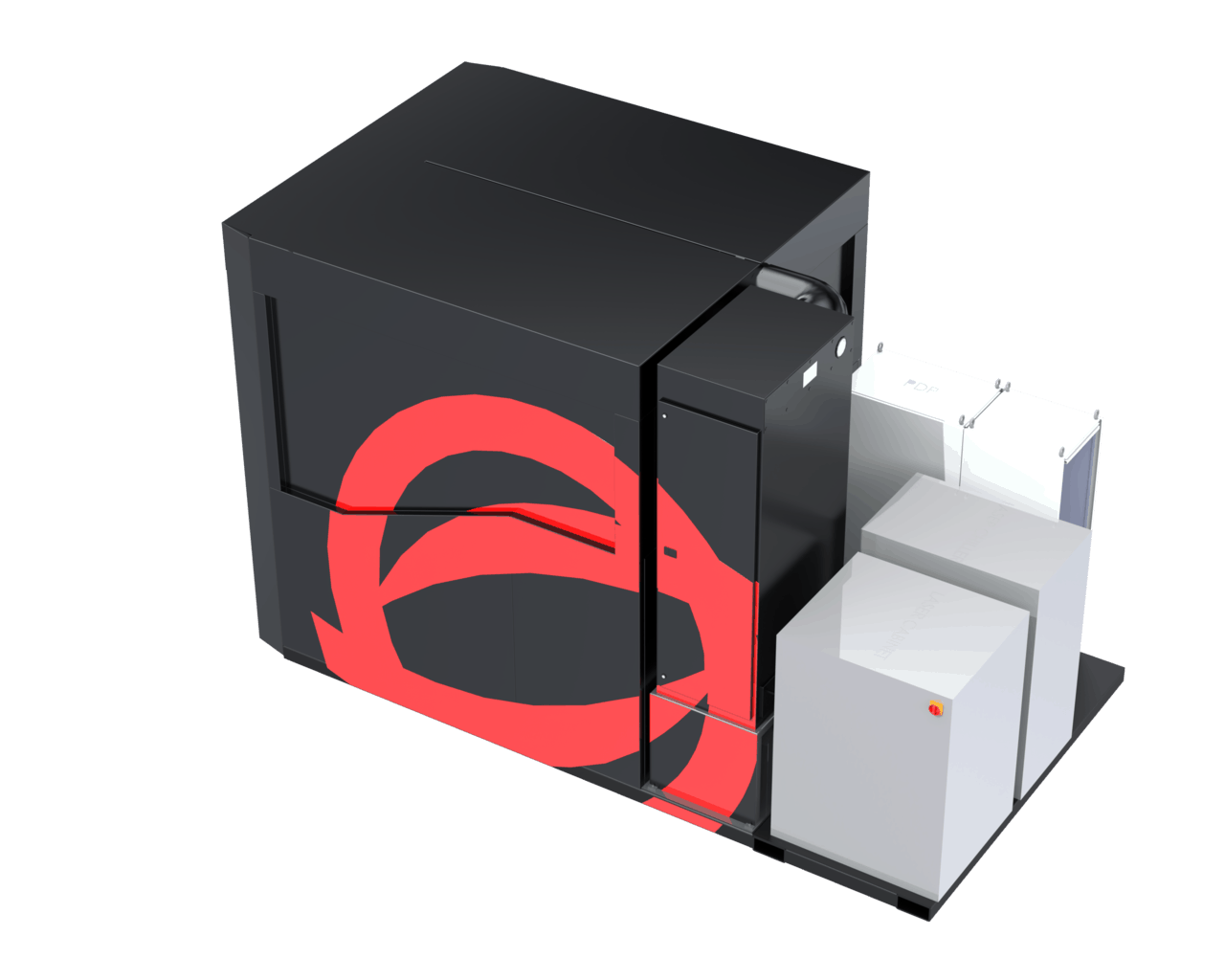

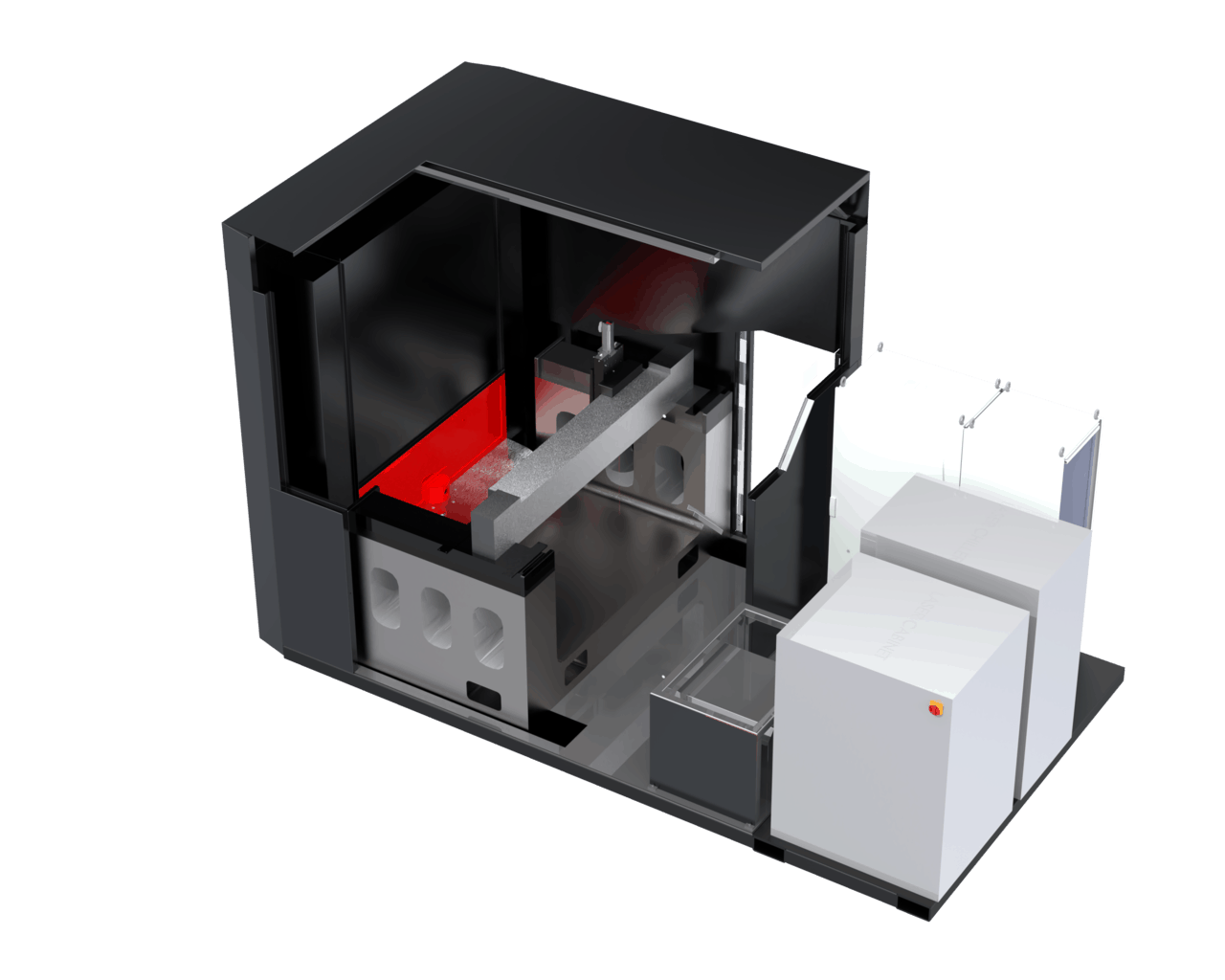

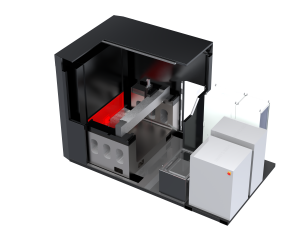

L-MS

The BOS L-MS is an advanced fiber laser solution equipped with a direct drive linear motion system with CNC motion control. Capable of up to 5-axes of coordinated motion, this precision machine offers the performance required to produce complex parts with tight tolerances.

L-MS MAX

When the application demands maximum precision and/or a larger working envelope for the laser process, the motion system can be upgraded to a gantry-style design.

LEARN MORE ABOUT LASER CELLS

Contact us today for more information, including pricing.