LASER CELLS

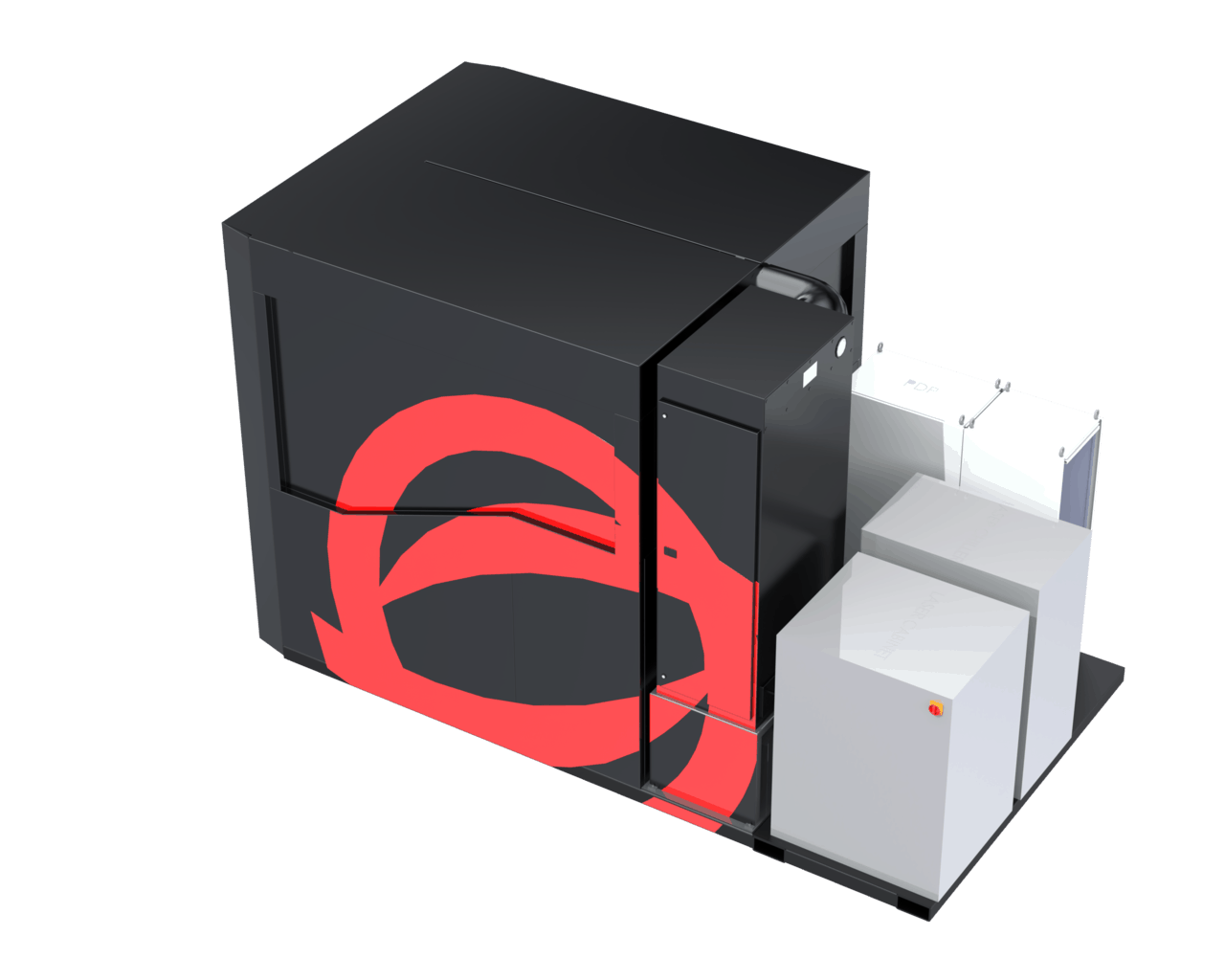

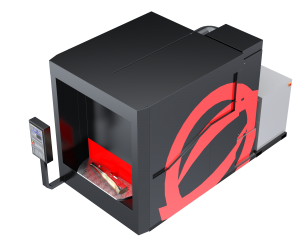

BOS® laser cells are turnkey solutions for automating industrial cutting or welding processes. Based on a modular, pre-engineered design, they can be customized to your needs to advance your manufacturing capabilities for the future. Increase competitiveness, productivity, quality, and profitability with BOS laser cells.

Features:

Pre-Engineered Design for Low Cost & Quick Delivery

Configurable & Modular

Ships Ready to Run

Drop-in-Place Installation

Operator Friendly

CSA & NFPA Safety Compliant Design

L-R

The BOS L-R solutions are configurable and based on a modular design, allowing you to meet changing market demands to ensure future competitiveness. The base model has a single robot with an integrated PLC control system and a flat table for part placement.

Laser Process: Cutting (Options for Welding)

Robot Reach: 1853mm

Input Power: 575V or 460V

FANUC M20iB High Accuracy Robot

Flat Table for Part Placement

1kW Fiber Laser

Integrated PLC Control System

Touch Screen Operator Interface

Robust Powder Coated Machine Frame

Controls Training (3-Day BOS Curriculum)

Part Fixture & Tooling

Additional Servo Positioners for Advanced Part Positioning

Welding & Remote Welding Configurations

Fume Extraction Equipment

Scrap Conveyor

Vision System

Offline Programming Software

Additional Robot

Automatic Doors

0.5-6kW Laser Source

Operator Interface for Manual Load

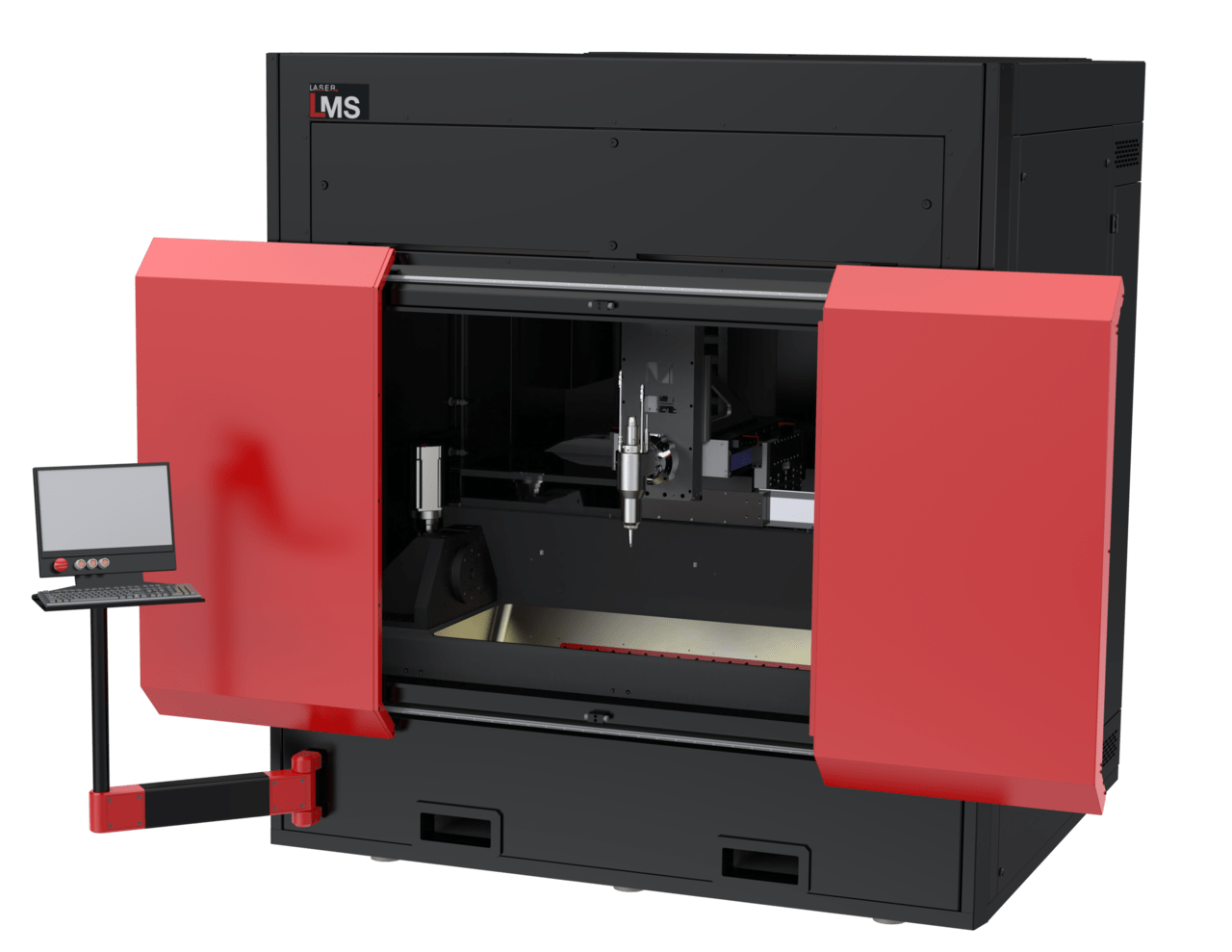

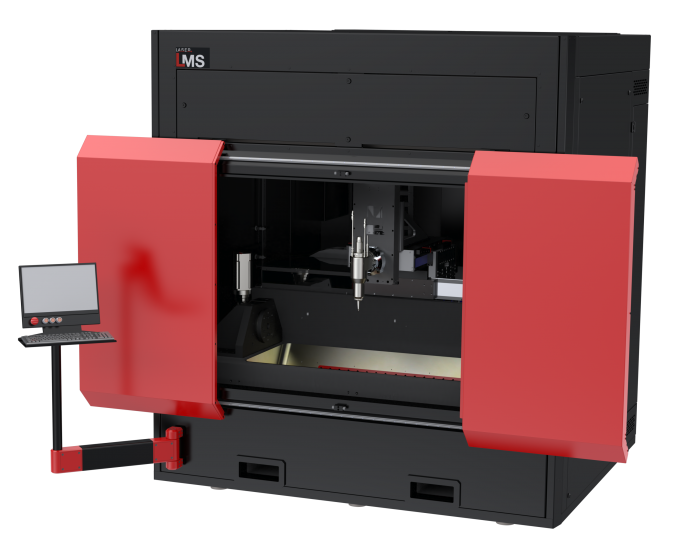

L-MS

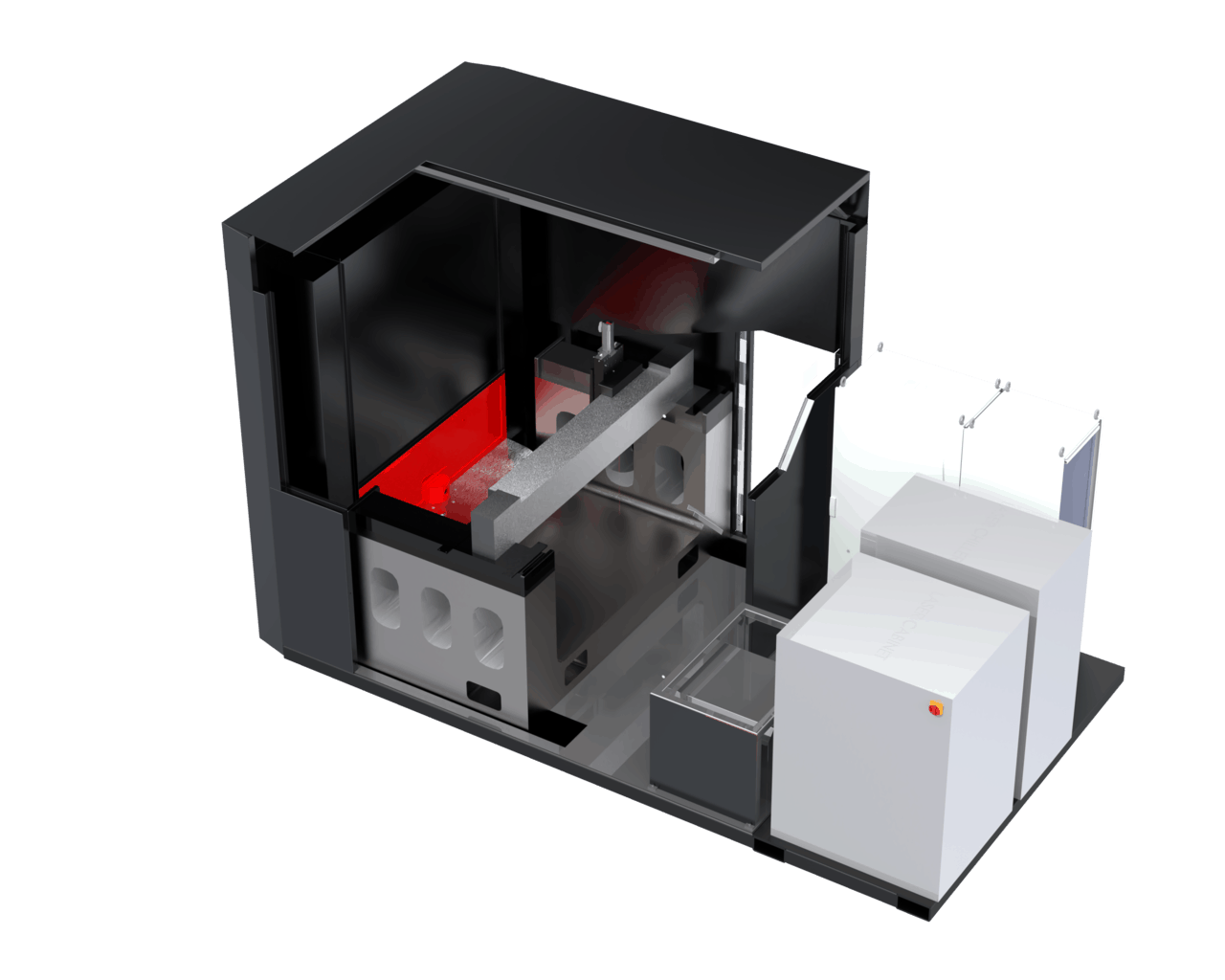

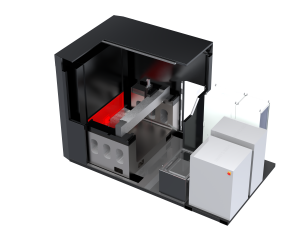

The BOS L-MS is an advanced fiber laser solution equipped with a direct drive linear motion system with CNC motion control. Capable of up to 5-axes of coordinated motion, this precision machine offers the performance required to produce complex parts with tight tolerances.

Laser Process: Cutting (Options for Welding)

Motion System Envelope: 1250mm x 200mm x 300mm

Max Processing Speed: 2000mm/sec

Input Power: 575V or 460V

3-Axis Coordinated Motion System

Direct Drive Linear Motors, Encoders, Servo Amplifiers

Mineral Cast Base

Flat Table for Part Placement

1kW Fiber Laser

Integrated PC-Based CNC Motion Control System

Touch Screen Operator Interface

Robust Powder Coated Machine Frame

Controls Training (3-Day BOS Curriculum)

Part Fixture & Tooling

Additional Servo Axes for Advanced Part Positioning

Welding & Remote Welding Configurations

Fume Extraction Equipment

Scrap Conveyor

Vision System

Offline Programming Software

Upgraded Motion System

Dual Rotate Laser Head (+2 Servo Axes)

0.5-6kW Laser Source

Safety Scanner for Operator Load

Automatic Doors

L-MS MAX

When the application demands maximum precision and/or a larger working envelope for the laser process, the motion system can be upgraded to a gantry-style design.

LEARN MORE ABOUT LASER CELLS

Contact us today for more information, including pricing.